A Deep Study Steel Foundries: Necessary Information and Market Trends

Metal foundries play a vital role in the production field, changing basic materials right into crucial elements. The processes included, from melting to quality control, are intricate and require accuracy. Recent developments are improving the industry, introducing automation and sustainability techniques. Yet, challenges continue, especially pertaining to labor and material costs. Comprehending these components is essential for grasping the current landscape and future instructions of factories. What exists in advance for this foundational market?

Comprehending the Metal Factory Process

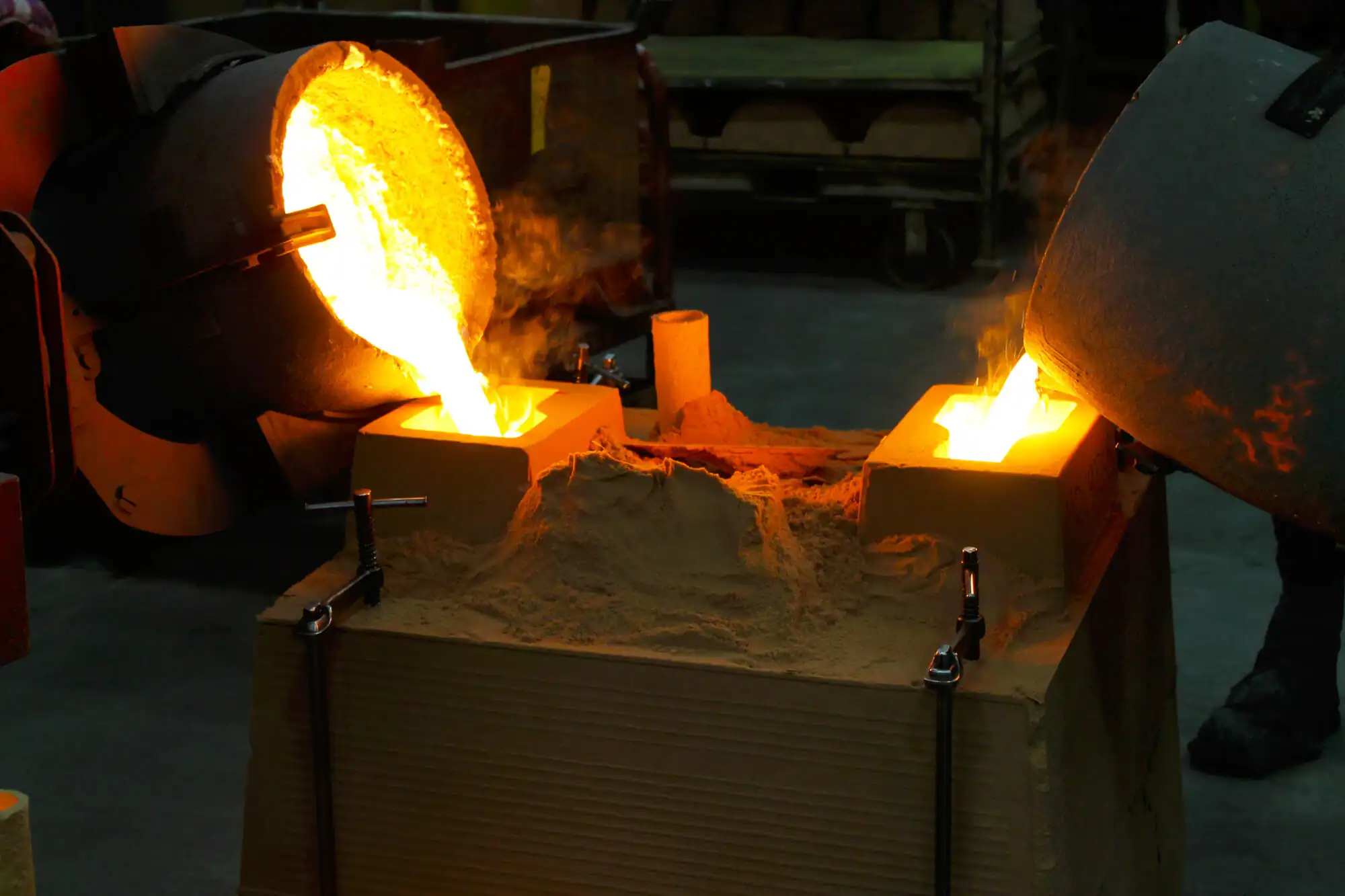

The steel foundry process may appear complex, it revolves around a few basic phases that transform raw products right into ended up steel products - Metal Casting. Originally, resources such as metal ores, scrap steel, and alloys are sourced. These products undergo melting in furnaces, getting to heats to dissolve the steel. As soon as molten, the metal is put into molds, where it cools down and strengthens into the wanted form

Complying with solidification, the spreadings are gotten rid of from the mold and mildews, leading to further processing. This may consist of trimming excess material, surface finishing, and warm therapy to enhance residential or commercial properties. Quality assurance evaluations are necessary throughout the process to guarantee that the end products fulfill called for specs and requirements.

Trick Technologies Fueling Factory Developments

The advancements in modern technology have greatly impacted the steel factory industry, driving developments that boost effectiveness and product top quality. Key modern technologies reshaping this industry include automation and robotics, which enhance procedures and minimize labor costs, enabling precision in mold making and metal pouring. Additionally, the fostering of 3D printing is changing pattern manufacturing, making it possible for intricate styles that traditional methods can not attain. Simulation software has emerged as a crucial tool, allowing shops to anticipate and fix potential spreading problems prior to manufacturing, therefore saving time and sources. The integration of IoT (Net of Points) gadgets improves tracking and information collection, helping with real-time adjustments to processes. Advancements in metallurgy, such as the growth of brand-new alloys, are increasing the capabilities of factories to produce more powerful and lighter components. With each other, these modern technologies are changing the landscape of metal foundries, driving them toward greater innovation and competition.

The Duty of Top Quality Control in Steel Casting

Quality control plays an essential function in metal casting, ensuring that each element meets rigorous specs and performance standards. This procedure entails a range of techniques, consisting of visual evaluations, dimensional measurements, and product testing - Aluminum Foundry. Foundries utilize quality control workers who keep track of each stage of manufacturing, from basic material selection to the end product inspection

By utilizing sophisticated technologies such as non-destructive screening and automatic evaluation systems, steel foundries can determine problems early in the production cycle. This positive strategy minimizes waste and lowers the possibility of pricey rework. Additionally, adherence to market standards, such as ISO qualifications, strengthens a navigate to this site factory's dedication to high quality, boosting consumer confidence and contentment.

Eventually, efficient quality control not only boosts the reliability and longevity of cast parts however also drives constant renovation within the factory, cultivating a society of quality and development in steel casting processes.

Sustainability and Environmental Practices in Foundries

As metal shops progressively recognize their influence on the environment, a dedication to sustainability has Recommended Site actually ended up being necessary in their operational methods (Metal Casting). Lots of foundries are executing energy-efficient technologies, such as electrical induction heating systems, which considerably minimize greenhouse gas discharges compared to conventional techniques. The adoption of recycled products, especially scrap steel, has likewise gained grip, minimizing waste and preserving all-natural resources

Additionally, water monitoring techniques are being enhanced to minimize consumption and avoid contamination. Many foundries are purchasing closed-loop systems that reuse water utilized in air conditioning and cleaning processes. In addition, dirt and emissions control technologies are being updated to ensure compliance with ecological laws.

Future Fads and Obstacles in the Metal Shop Industry

Arising trends in the metal shop industry highlight a change towards progressed innovations and ingenious techniques targeted at improving efficiency and competition. Automation, including robotics and expert system, is increasingly adopted to minimize and simplify operations labor prices. Additionally, the integration of Industry 4.0 modern technologies helps with real-time information evaluation, making it possible for better decision-making and anticipating maintenance.

Obstacles persist. The sector faces an experienced labor lack, necessitating investment in workforce training and advancement. Varying raw material costs and supply chain interruptions present substantial obstacles. Ecological guidelines are ending up being more stringent, pushing foundries to embrace sustainable techniques that that site can be pricey originally yet useful long-lasting.

Furthermore, the need for lightweight and high-performance alloys is increasing, requiring factories to innovate their products and processes. Stabilizing these trends with ongoing challenges will certainly be essential for the future success of the steel shop market.

Frequently Asked Questions

What Is the Background of Metal Shops?

How Do Foundries Determine Steel Alloy Compositions?

Foundries figure out steel alloy structures with a mix of empirical screening, computer modeling, and sector requirements. They analyze wanted residential or commercial properties, application requirements, and cost-effectiveness, making certain the final alloy meets certain efficiency requirements for desired uses.

What Are the Many Typical Factory Products Utilized?

One of the most usual shop products include cast iron, aluminum, bronze, steel, and brass. These materials are preferred for their toughness, resilience, and adaptability, making them appropriate for numerous applications in manufacturing and building and construction.

How Do Foundries Deal With Hazardous Waste Disposal?

Factories manage contaminated materials disposal with strict adherence to ecological policies, employing specialized control systems, reusing campaigns, and partnerships with qualified waste administration companies to ensure certified and secure disposal of poisonous materials.

What Job Opportunities Exist in the Metal Factory Industry?

Metal factories play an important duty in the manufacturing sector, transforming raw materials into vital elements. The steel shop procedure may seem facility, it rotates around a couple of fundamental phases that transform raw products right into completed metal items. The innovations in modern technology have substantially influenced the steel shop market, driving advancements that enhance effectiveness and product high quality. The history of steel foundries dates back to ancient civilizations, where artisans first thawed steels to produce devices and decorations. The steel factory industry offers diverse occupation possibilities, consisting of roles in engineering, high quality control, procedures administration, and environmental compliance.